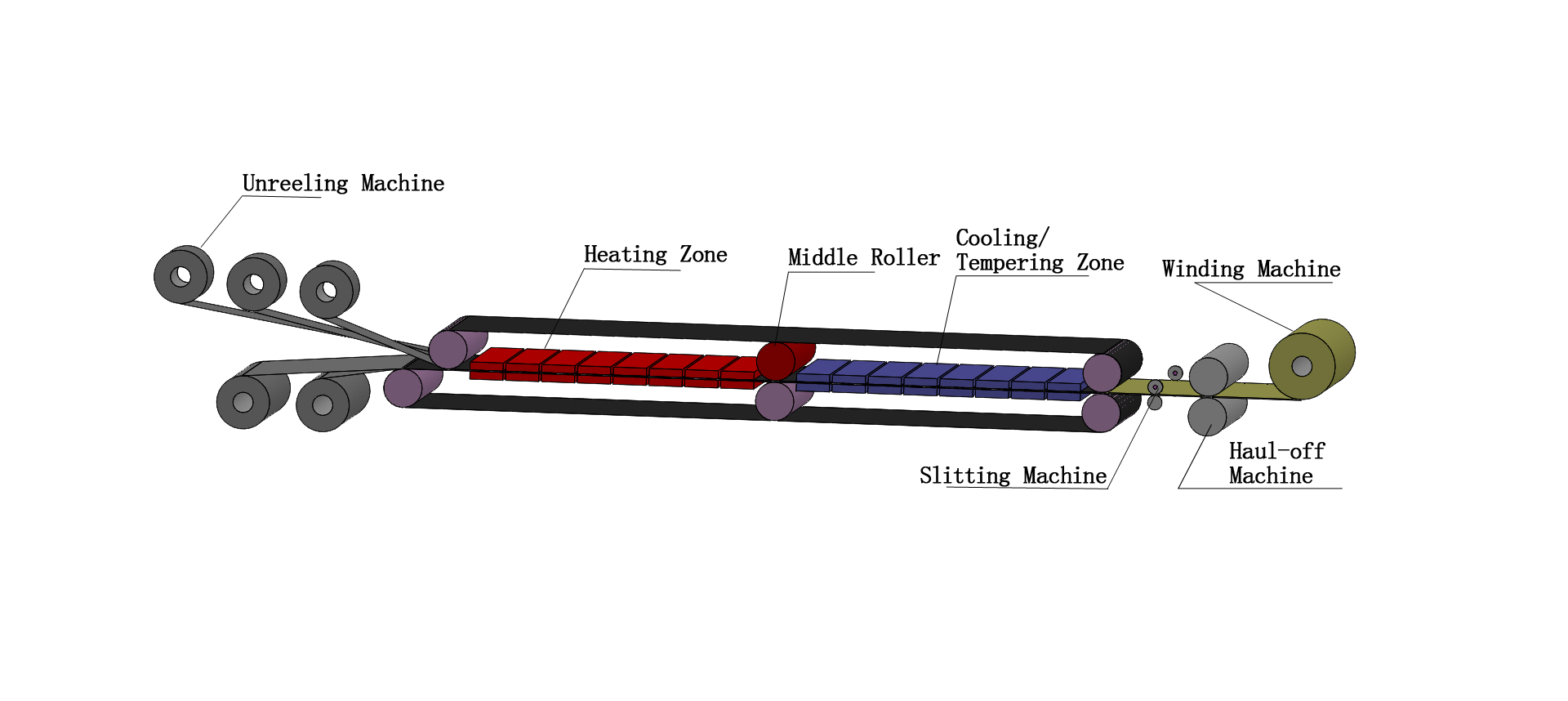

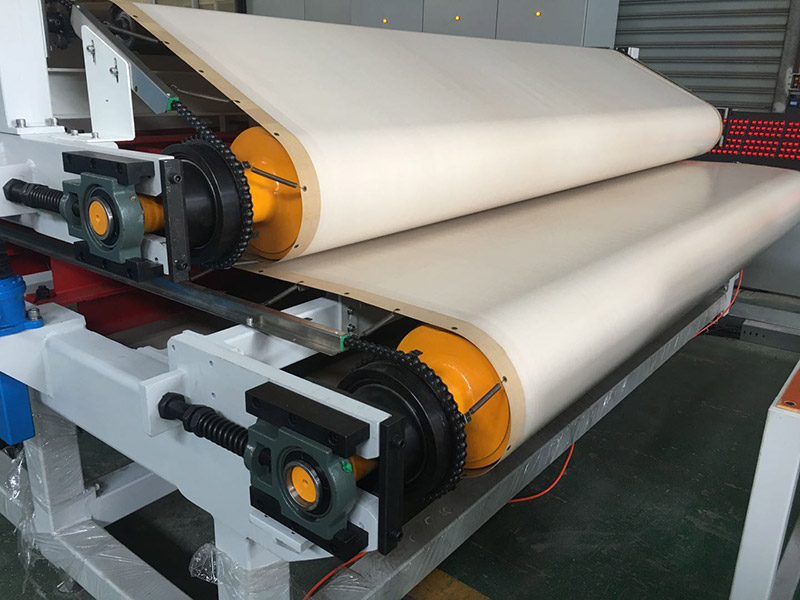

Double Belt Presses For Fiber Reinforced Thermoplastic Composite Laminates Or Thermoplastic Honeycomb Sandwich Panels

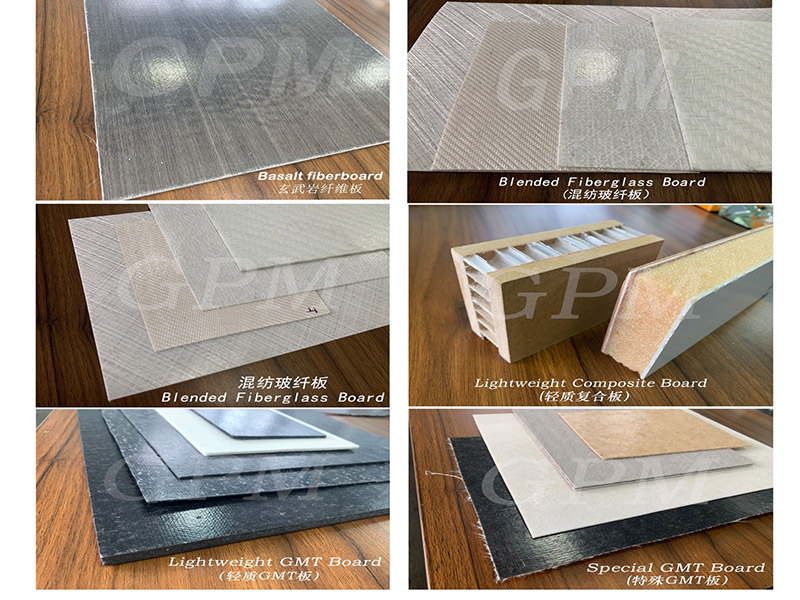

Continuous fiber-reinforced thermoplastic composite material-a new type of thermoplastic composite material with high strength, high rigidity, high toughness, and recyclability, which is formed by thermoplastic resin as the matrix and continuous fiber as the reinforcing material through processes such as resin melt impregnation and extrusion.

CFRT sheet

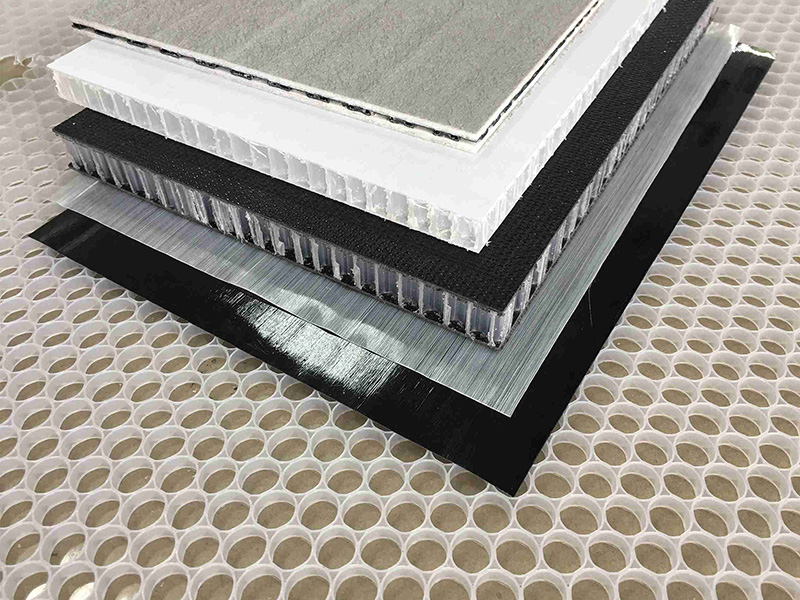

CFRT sheet is a thermoplastic composite sheet made of CFRT unidirectional cloth according to one or more combinations of 0°, 45°, -45°, 90°, etc., followed by hot and cold pressing. It can also be combined with other high-performance core materials, such as honeycomb panels, polyurethane foam, balsa wood, solid wood compression panels, etc., or combined with non-woven materials to form new sandwich composite panels.

Product advantages: continuous fiber can provide maximum strength and rigidity; the product has excellent interlayer shear performance and high impact resistance; the layering method, thickness, reinforcing material type, and fiber volume content of the sheet can be customized to meet the needs of different industries Customer requirements; no fabric lines on the product surface; corrosion resistance, mildew resistance, easy to clean, not affected by chemical cleaning agents; weldable, easy to cut, install and repair; can be hot-pressed, short molding cycle; can partially replace thermosetting glass fiber reinforced plastic, Aluminum and stainless steel sheets are suitable for the lightweight needs of vehicles; it is environmentally friendly, recyclable, and sustainable.

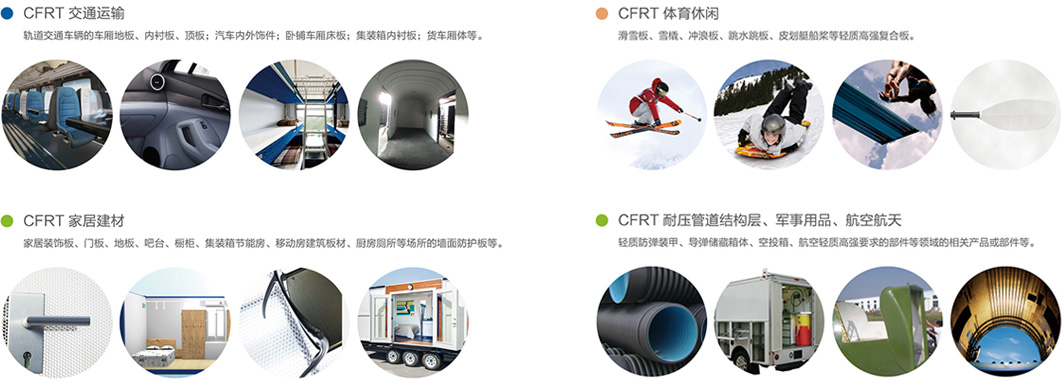

The main application areas of CFRT:

The floor, inner lining, roof, interior and exterior trims, ship trim, container lining, and roof of transportation rail transit vehicles; interior and exterior trims (used in the development of rear anti-collision beams and other high-strength products) Applications)

Sports and leisure (snowboards, sleds, surfboards, diving springboards, oars); pressure-resistant pipeline structure layer; light-weight bulletproof armor for military supplies, missile storage boxes, airdrop boxes; light-weight and high-strength components for aviation and other related fields Products or parts.

Model and parameter选型参数

Model产品型号 | GP1700 | GP2300 | GP3000 | GP3400 |

Belt Width(mm) 皮带宽度 | 1700 | 2300 | 3000 | 3400 |

Effective width(mm) 有效宽度 | 800-1550 | 1450-2000 | 2000-2750 | 2300-3050 |

Heating length(mm) 加热区长度 | 1500-3000 | 1500-3000 | 2500-4000 | 2500-4000 |

Heating mode 加热方式 | Electrical heating 电加热 | Electrical heating 电加热 Oil heating 油加热 | Electrical heating 电加热 Oil heating 油加热 | Electrical heating 电加热 Oil heating 油加热 |