Introduction of RTP Pressure-resistant pipe

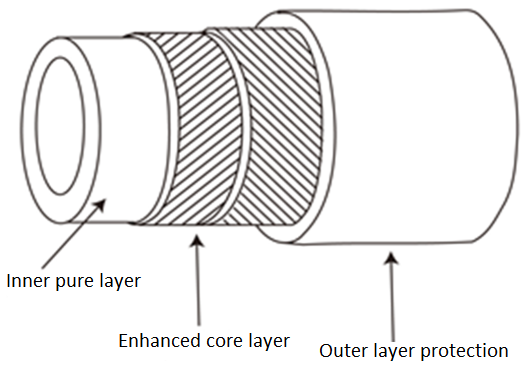

The continuous glass fiber reinforced composite pipe (CF-RTP) is a continuous glass fiber reinforced high pressure pipe. The pipe is divided into an inner liner layer, a reinforcing core layer and an outer protective layer. The inner liner is made of PE (or PP/PA/PERT) as the main material, which acts as a medium for guiding, anticorrosive and conducting internal stress; the outer protective layer acts as a protective core layer and conducts external stress. The reinforcing core layer is subjected to multi-layer interleaving to bear the effects of stress, temperature and tube creep resistance. Mainly used in heat pipes, hot spring pipes, oil pipes and water pipes, it is a new type of high pressure resistant pipe that replaces conventional plastic pipes.

Specifications and properties of commonly used RTP pipes

Common pipe diameter: 1.5-20 Inch

Common pipe pressure level:

1.5-6 Inch diameter(3.5-30MPa)

8-20 Inch diameter (2.5-5.5MPa)

Glass fiber UD tape winding layer : 4-16 layer

Glass fiber UD tape winding thickness: 1.2-6mm

Suitable for UD tape width: 45-300mm

Brief description of production line

Brief description of the production line: raw material dry feeding → inner tube extrusion → sizing sleeve → vacuum setting spray → one traction → infrared heating → multi-stage winding unit → extruder coating → spray cooling water tank → laser printer → Crawler tractor → planetary cutter → pipe stacker (winding)

NO | Model of RTP pipe production line | Pipe diameter range | Pressure rating | Reinforcement layer thickness |

1 | GP-RTP110 | 40-110 | 3.5-30 | 1.2-6 |

2 | GP-RTP200 | 110-200 | 2.5-5.5 | 1.2-4.2 |

3 | GP-RTP400 | 250-400 | 1.5-3.5 | 1.2-3 |

Production line advantage inttroduction

1.The equipment adopts pre-dip tape winding/in-situ consolidation process, which adopts hot air heating to realize winding and heating consolidation at the same time; one winding machine can carry 4 trays or 2 trays according to caliber and Use to choose different models.

The special tube surface and the heating radiation process of the UD belt ,have obvious advantages over other types of heating:

Winding technology | Increase bandwidth | Processing heat transfer | Reaction time | Winding path |

Laser | Difficult | Radiation local point | Fast | Harsh |

Infrared | Difficult | Radiation, convection, local line | Fast | Harsh |

2.According to the design of equal-strength structure, different matching bandwidths are adopted according to different pipe diameters; broadband and narrow-band flexible use;

3.Using a process in which the strip and the strip are lapped, a network structure is formed between the reinforcing layers

4.At present, the caliber range is 50-600MM, and the bandwidth is 50-400MM. It is at the leading level both at domestic and international.

5.Provide solutions according to different needs of customers.